What is ICF?

Insulated (or insulating) Concrete Form is a system of styrofoam blocks that interlock (not unlike LEGO) to create a permanent formwork, into which rebar is placed and then concrete is poured. A properly constructed ICF building far outperforms other types of conventional construction in terms of energy usage and user comfort. ICF is a great system but it isn’t in wide use yet. Only a small percentage of new homes built each year use an ICF system, but it has been steadily increasing in popularity for the past couple of decades.

The ICF walls are a big feature of this house. Here’s a closeup looking inside one of our walls as they were stacking it.

The blocks in our build were made by a company called Fox Blocks, at their plant in Phoenix. We used them because the installers we hired preferred to use them, and it was all the same to me. The dimensions can vary by company, but Fox Blocks are 16″ high and 48″ long. Each foam panel side is 2 5/8″ thick, and the center cavity in our walls is 6″ of concrete. This makes the whole wall 11 1/4″ thick. They also make them in 8″ and 10″ concrete thicknesses.

Here are our blocks all bundled on their palettes, ready to be stacked in place on top of the footings.

ICF Specialist

We were lucky to have a really good company out of Phoenix called “ICF Specialist” do our ICF work. They did a great job and I would be happy to work with them again. They were extremely knowledgeable and professional, and I got the sense that their main focus was to get the job done right so that I would be happy. And, I am happy!

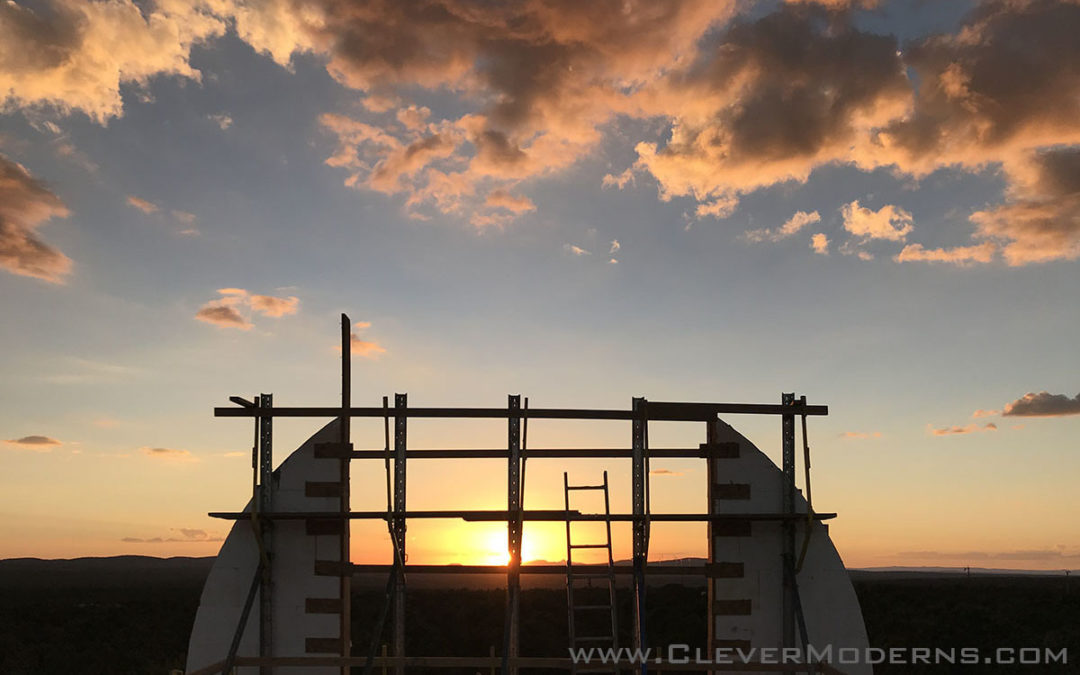

They stacked the “boxy” part of the building first, which took a few days. When it came time to start on the curve where the end wall goes up into the Quonset, we too measurements from our Workshop Hut to confirm the diameter. We had ordered all three of our first buildings at the same time, and of the same size, for this very reason. (Well, not exactly, as we didn’t have ICF in mind back then, but we knew we wanted all three buildings to be the same size arch so that we could experiment on the first two before moving on to the house.) We measured and then subtracted a couple inches off the radius, to give us some wiggle room when it comes time to put the Quonset hut arches up over the walls.

The rectangular wooden pieces you can see in the photos are placed and screwed into the walls to help hold it all together so it doesn’t blow out under the weight of the wet concrete. They’ll be stripped off later. They also used a lot of diagonal steel braces that had a kind of scaffolding catwalk integrated into it at the top. It’s a very clever system overall.

Pouring the Concrete

Then it was the day of the pour! They had a HUGE concrete pump with a boom that could get the concrete into the tops of the walls twenty feet above the ground. It was amazing. The pour went off without a hitch.

Stripping the Forms

After they poured the concrete, it was several days before they came back and stripped off the bracing and temporary wooden tie pieces. Now you can really start to see the size and shape of the house!

While the bracing and scaffolding were still in place, we took advantage of them to do some drilling into the top of the walls where the base plates will go. It was exciting and fun to finally get our own hands dirty after watching all these pros do their work.

Next step will be to pour the floor slab, and then after that it’s Quonset hut arches for the roof!

Curious about Quonsets? Ready to learn more about these bizarre, amazing, shiny, round, prefab structures? Drop your info below and I’ll start you off on my email tutorial series. Looking to build an inexpensive but beautiful home debt-free? Considering going off-grid? Or are you just tired of the same old same old and want something unique and beautiful? A Quonset House might be the answer for you.

Follow us on Instagram and Facebook. We also have a private Facebook group called DIY Quonset Dwellers, where we share discussion, design, and construction tips with others who are interested in building their own Quonset hut house. With over 6,000 members and counting, the Facebook group has grown into an amazing resource all of its own! Learn more and request to join the Facebook group here.

This is so cool! I am thinking about building a quonset hut on 20 acres. You guys rock!

Hey Jon, thanks! Quonset on!

Hi, I’m dreaming of someday building one of these! Do you find it cheaper to build the walls with ICF and no extra insulation or is it better just using the arches and framing and spraying insulation on the interior? Mind you, I would have to hire someone to do either process.

The ICF definitely added extra expense versus if we had used an S model and just insulated the inside with spray foam.

The ICF is a great system, but it was a long, circuitous route that led us there, and I think if we were starting over knowing what we know now we would probably do it differently. For a more cost-effective build, using an S model is probably just as good for 90% of people wanting to do something like this.

What about using ICF’s for just end walls on a Q model structure?

I think they would be an upgrade from traditional wood frame end walls with foam and now that wood is so ridiculously high, they claim ICF is actually cheaper.

I am thinking about placing my Q model on ICF stem walls. How thick does the ICF wall need to be in order to use steelmaster baseplate system?

It’s a little more complicated than that. You need a full 12″ minimum of concrete and the ICF insulation on the outside edge at the top of the wall will be in the way. You have to cut it back and design the top of the wall to accommodate the base plate. You really need to be working with a structural engineer who is experienced with ICF to design the walls. You really have to get the rebar right or your wall can fail.

Hey Earl,

Stumbled on your quompound site awhile back, have been enjoying the Quonset look and ideas before finding your site also have contemplating the icf block builds.

Last night was dreaming combining the two since I didn’t care for the steel master window situation, and I thought icf sidewalls with windows would be better combined with icf end walls! Currently I live in SoCal stick house, yet I want to leave EXPENSIVE overpopulated California!!

Let’s talk soon, please?

Just listed my home.